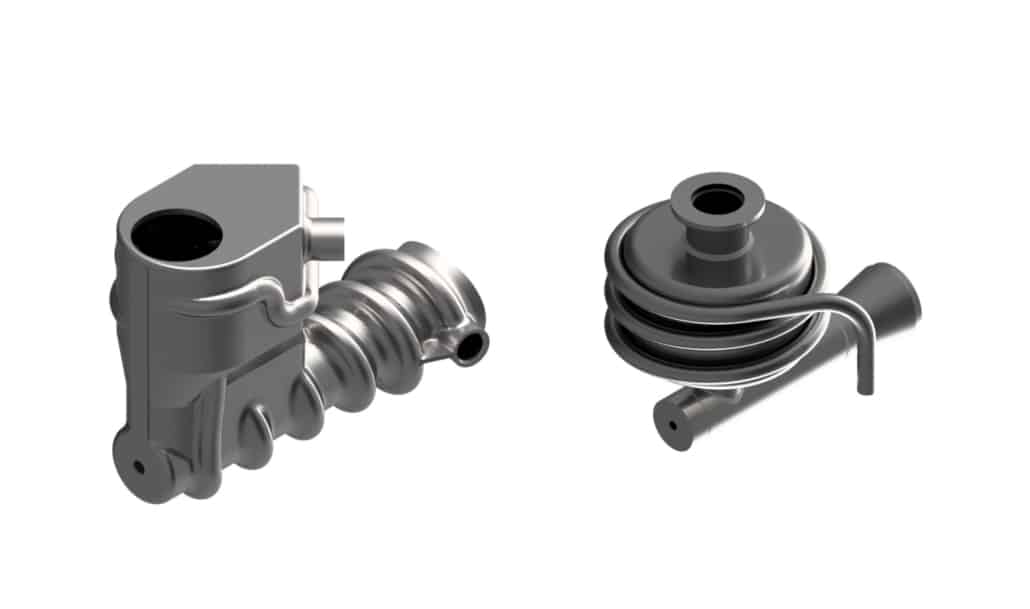

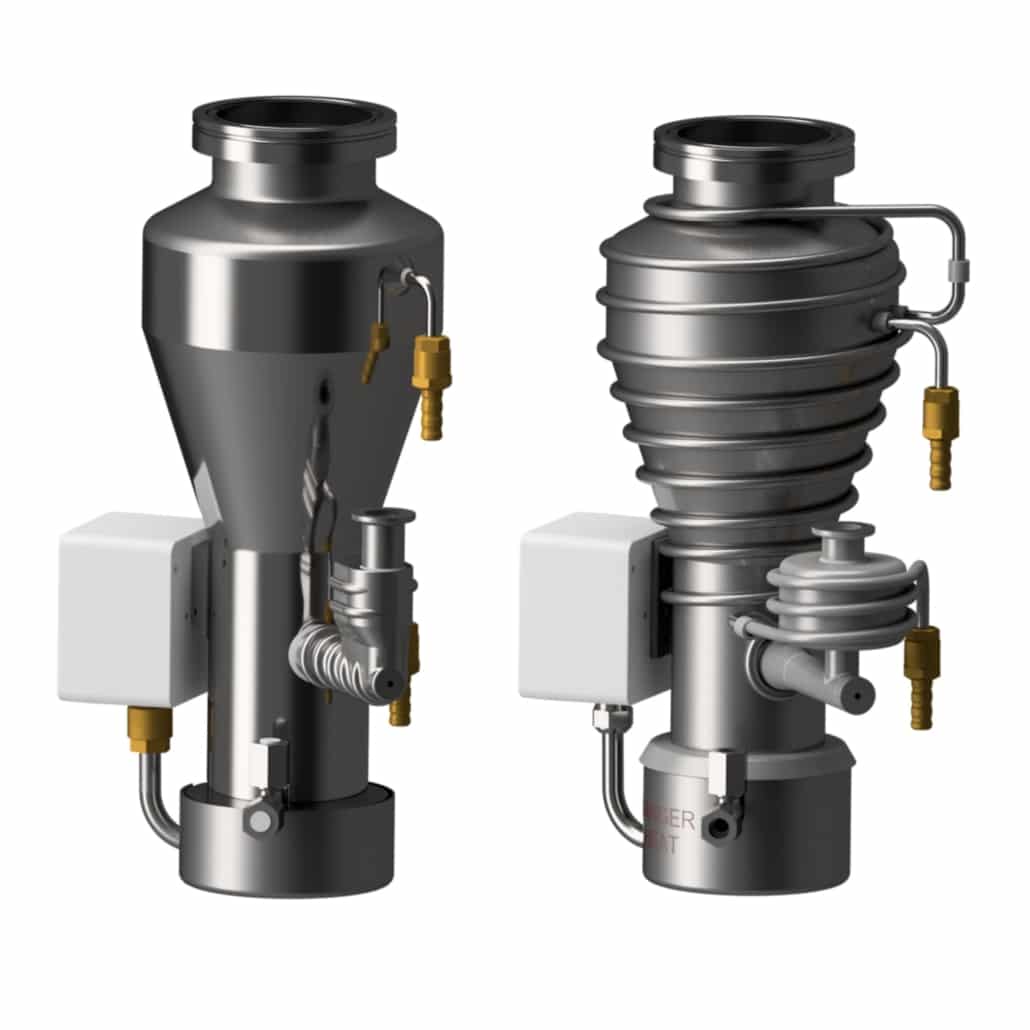

A complex sub-assembly was replaced by a single 3D-printed component during a redesign. This eliminates the need for several individual parts, significantly reduces the number of soldered and welded joints and eliminates leakage problems in this area.

The initial situation

The company HSR AG from Balzers was faced with a task that many of us are familiar with. The penultimate stock items of a product had been ordered and delivered, so it was high time to reorder. But fortunately, in this case it was not a problem: The assembly consisted of so many individual parts, which had to be screwed, welded and soldered together with enormous effort. A minimum quantity would have been unavoidable for this to lead to reasonably acceptable prices. In addition, only someone with a great deal of experience would have been able to solder the tubes and the old soldering gauges would also have had to be replaced.

That must be easier!

The solution

From an earlier project (plate with internal cooling), a design engineer at HSR AG was already familiar with the additive manufacturing of metal at BSF Bünter AG. A short email including a screenshot later, a team meeting was organised. Together, they discussed the separation of parts and repeated the 3D print-compatible design. A short time later, the printed components were ready for assembly. In a later step, further parts were replaced with AM components.

The hard facts in figures

- Reduction of individual parts from 9 to 2

- Reduction in time required for soldering / welding from 8 hours to 2 hours (entire assembly)

- No new soldering/welding jig at CHF 500 (one-off per part size)

- Total cost reduction of 30% compared to the old solution (entire assembly)

- this with batch size 2 instead of 10 as before

- Reduction in procurement time by approx. 50%

Do you also want to realise the full potential of your products? Contact us for a non-binding consultation!