Creating ideas and visions. With us as your partner.

BSF Bünter AG brings its customers' ideas and visions to the right data interface for further processing in 3D. With CAD-CAM technology, the company has a direct interface from design to programming to the CNC machine, for cubic, rotary and selective machining.

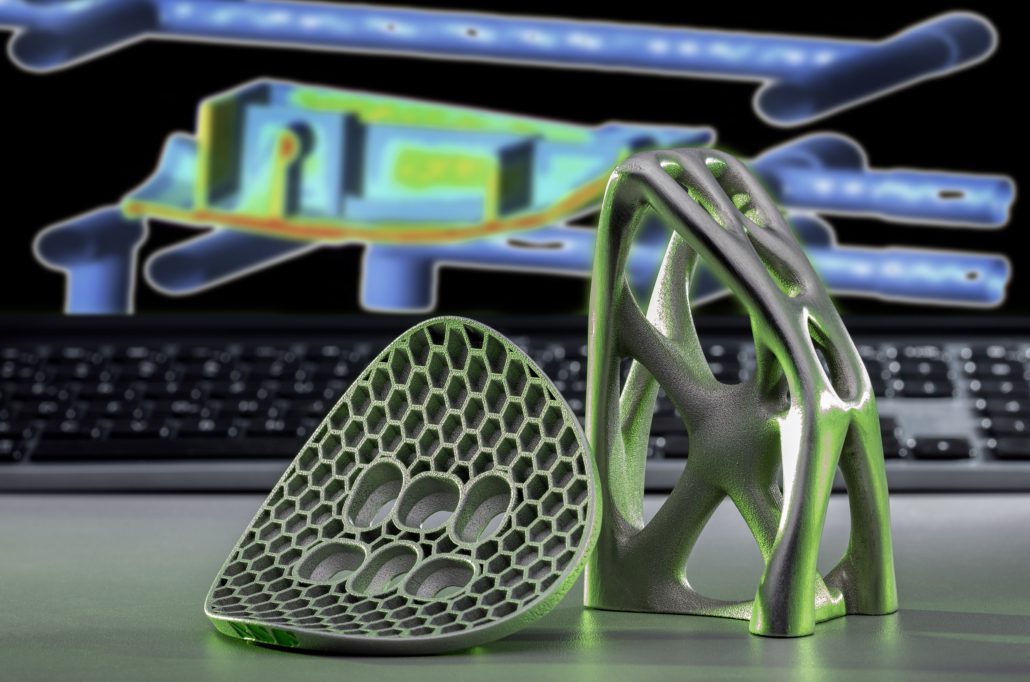

Do you need support with additive-optimised design?

BSF Bünter AG helps its customers to design components that are to be manufactured using additive manufacturing. A great deal of experience is required to utilise the maximum potential of this innovative technology. Our design department specialises in conformal cooling. Injection moulding tools that are produced using additive (also known as generative) manufacturing can be equipped with temperature control channels that are optimally adapted to the cavity. This significantly more regular and faster cooling can considerably reduce the distortion of your injection moulded parts, while at the same time shortening cycle times.

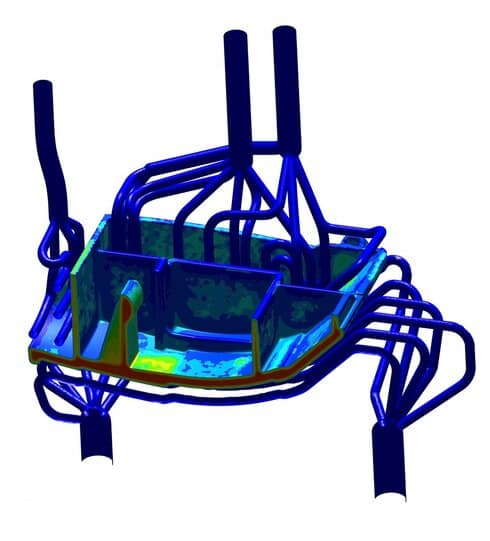

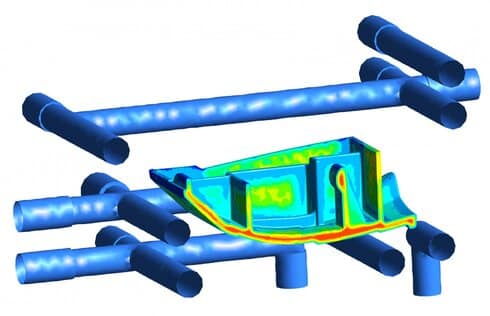

30 - 50% Shorter cycle times and improved quality at the same time - you too can benefit from the advantages of conformal cooling, together with your service provider BSF Bünter AG. In the following video window, cooling simulations of conventional moulds (with straight cooling holes) and of near-contour cooling channels (produced using SLM) are played alternately. It can be seen that with conventional cooling, it is mainly the mould that is cooled. With near-contour cooling, on the other hand, attention is paid specifically to the component surface. Further examples are shown in the graphics.

Contact us

BSF Bünter AG

Dammstrasse 3

9435 Heerbrugg

Switzerland

Opening hours

Monday - Friday: 07:00 - 17:00

Saturday & Sunday: Closed

Latest news

25th anniversary Charlotte Dalla Rosa23 June 2025 - 15:09

25th anniversary Charlotte Dalla Rosa23 June 2025 - 15:09 10-year anniversary Susanne Reiter5 June 2025 - 10:56

10-year anniversary Susanne Reiter5 June 2025 - 10:56 40 years of BSF Bünter AG - Picture gallery11 February 2025 - 11:11

40 years of BSF Bünter AG - Picture gallery11 February 2025 - 11:11

Obtain a quote

Please send us an enquiry and we will get back to you as soon as possible.