Whoever visits our homepage or Facebook page The following already knows that there is a building site next to BSF Bünter AG. However, we have not yet officially revealed what exactly is being added to our existing company:

The extension will increase our production area at ground level, and the upper floor will be dedicated solely to additive manufacturing. We are incorporating our experience from 4 years of LaserCusing into the space planning in order to organise the work as reliably and efficiently as possible. This is how BSF Bünter AG is creating the only centre for additive manufacturing of metal in Switzerland! The residential building was demolished, the ground was levelled and the foundations were poured last week. On our Homepage and Facebook page photos of the construction progress will be published on an ongoing basis, so stay tuned and check back from time to time.

From 15 to 18 November 2016, Basel will host the Prodex / Swisstech will take place. BSF Bünter AG will also be represented at the special show "Professional 3D-Printing" in Hall 1.1 at Stand E50. Come by and be inspired by our practical components for innovative solutions in your company!

Kind regards

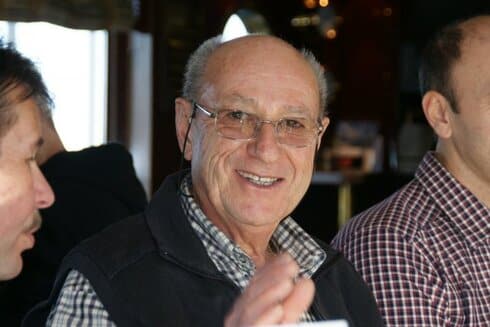

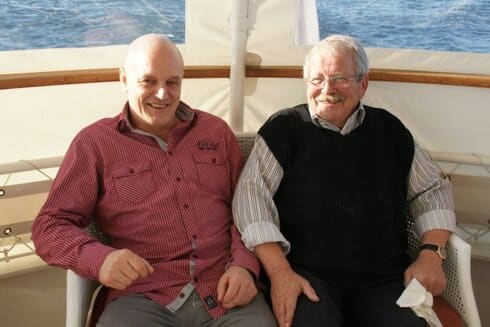

Kurt and Fabian Graber

BSF Bünter AG