Dear Business Partner

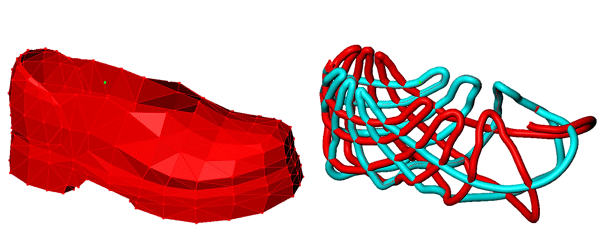

While the last orders before Christmas are still being processed in our production department, we have once again invested in an exciting innovation. In our brand new wire erosion machine includes a rotary axis. This allows us to machine your parts from several sides in a single clamping operation and thus achieve even more precise tolerances. It is also possible to rotate the component and virtually turn or cylindrically grind it on the eroding machine. The minimum wire diameter is just 0.05 mm, which is thinner than a human hair.

Would you have thought that we could completely wire-cut the bolt from this drawing?

The entire BSF team wishes you a relaxing time and a happy new year. We will be back in action for you from 2 January 2019.

.png)